Hagaajinta Saxnaanta iyo Hufnaanta: Doorka lama huraanka ah ee Mashiinnada Qallooca Haydarooliga ee CNC ee Qallooca Casriga ah ee Birta

Video

sharaxaada alaabta

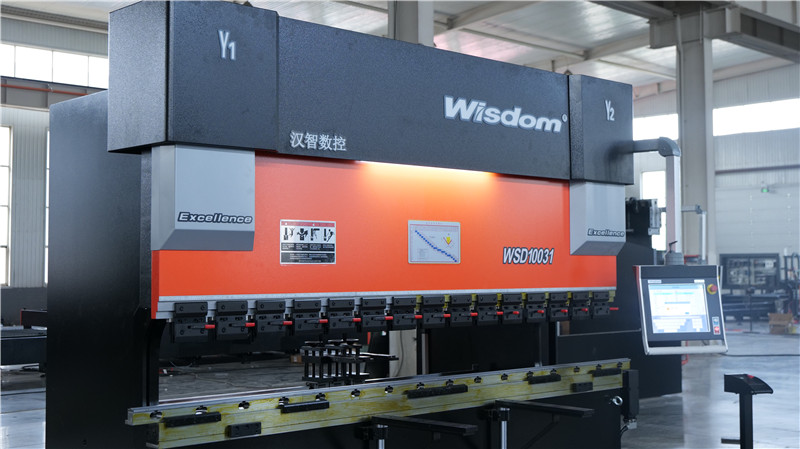

Mashiinka foorarsiga haydarooliga ee CNC:

Mashiinnada foorarsiga haydarooliga ee CNCwaa mashiino si gaar ah loogu talagalay inay laalaabiyaan xaashida birta ah qaabab iyo qaabab kala duwan.Qalabkan xoogga badan waxa uu isticmaalaa xoog biyo-diid ah si uu cadaadis ugu saaro biraha xaashida ah, taas oo u oggolaanaysa inay si sax ah u foorarsato biraha xaashida ah si joogto ah si ay u daboolto baahiyaha wax soo saarka ee kala duwan.Nidaamkeeda kantaroolka nambarada kumbuyuutarka (CNC) ayaa si sax ah u maamula habka foorarsiga, isaga oo hubinaya saxnaanta gaarka ah iyo soo celinta.

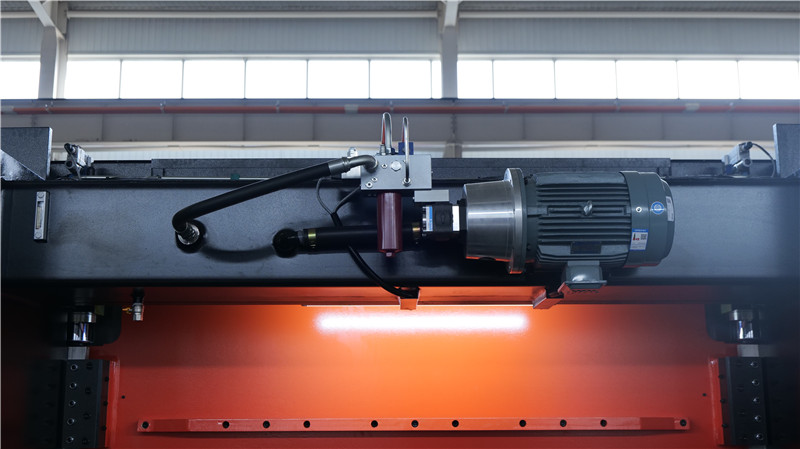

Awooda tignoolajiyada biriiga saxafada Crown:

Mid ka mid ah sifooyinka kala duwan ee CNC hydraulicbiriiga riixwaa tignoolajiyada ugu horeysa ee bireega saxafada.Habkan caarada ah ayaa magdhow u ah leexinta laydhka iyo sariirta mashiinka inta lagu jiro foorarsiga.Qaabka biriiga saxafada ee convex-ku waxay hubisaa qaloocsanaan siman oo joogto ah dhererka xaashida birta oo dhan iyadoo si toos ah u hagaajinaysa booska xajinta haydarooliga.Tani waxay meesha ka saaraysaa khaladaad kasta oo iman kara oo ay sababaan isbeddellada walxaha ama qallafsanaanta mishiinka, taasoo keentay qaloocnaan qumman iyo xaglo qumman.

Saxnimada waxay buuxisaa waxtarka:

biriiga CNC haydarooliga si aan dadaal lahayn isku daraa sax ah iyo hufnaan wakhtiga, iyaga oo ka dhigaya qalab lagama maarmaanka u ah qalloocinta birta casriga ah.Mashiinkani waxa uu qaataa tignoolajiyada horumarsan sida cabbiraadda xagasha tooska ah iyo kontoroolka dhidibada badan, waxa uuna si sax ah oo degdeg ah u dhamaystiri karaa foorarsi adag.Nidaamka CNC wuxuu daryeelayaa xisaabinta, u oggolaanaya hawlwadeenku inuu galo xuduudaha loo baahan yahay iyo mashiinku ka dibna la wareego, isagoo hubinaya si degdeg ah, foorarsi sax ah.Isku dhafka aan kala go 'lahayn ee gelinta buug-gacmeedka iyo saxnaanta tooska ah ayaa si weyn u yaraynaysa wakhtiga wax-soo-saarka waxayna kordhisaa waxtarka guud ee habka wax-soo-saarka birta.

Fur dabacsanaanta birta qaloocinta:

Mashiinka foorarsiga haydarooliga ee CNC waa mashiinno badan oo shaqeynaya oo awood u leh inuu leexiyo noocyo kala duwan oo bir ah, oo ay ku jiraan aluminium, birta, naxaasta, iwm .La qabsigeedu waxa uu u sahlayaa mishiinku in uu qabto hawlo foorarsi oo fudud iyo mid aad u adagba, taas oo ka dhigaysa hanti muhiim u ah warshadaha birta.

Gebogebadii: Mashiinnada foorarsiga haydarooliga ee CNC ayaa isbeddel ku sameeyay warshadaha wax soo saarka biraha leh shaqadooda sare iyo astaamo cusub.Mashiinkan ayaa isticmaalabareegga saxaafadda taajkatignoolajiyada si ay u keento saxnaanta iyo is-waafajinta birta, hubinta natiijooyin aan cillad lahayn.Isku dhafka nidaamkeeda CNC iyo kontaroolada otomaatiga ah waxay kordhisaa waxtarka waxayna yareysaa waqtiga wax soo saarka.Intaa waxa dheer, dabacsanaanta ay bixiso marka la eego agabka iyo ikhtiyaarka habaynta ayaa sii adkaynaysa heerka ay ku sugan tahay oo ah qalab lagama maarmaanka u ah biraha casriga ah.Maaddaama baahida loo qabo samaynta birta adag ee saxda ah ay sii socoto inay koraan, biriiga CNC hydraulic press ayaa weli ku jirta safka hore, taasoo horseedaysa mustaqbalka birta qaloocsanaan lahayn.

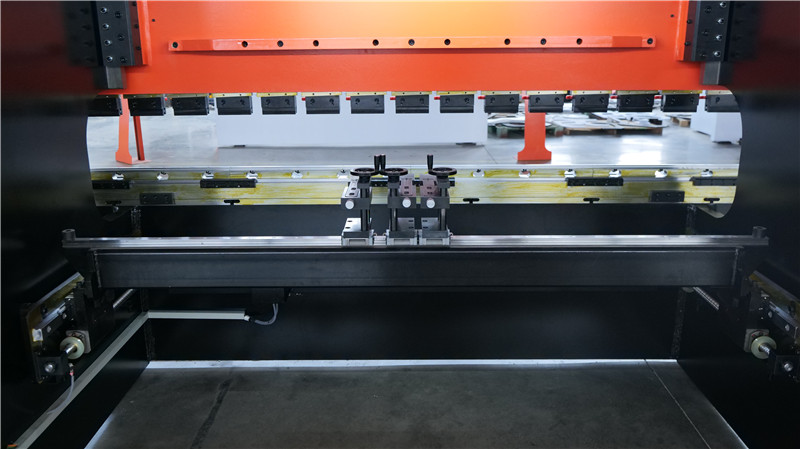

Hababka qaloocida waxaa ka mid ah leexinta xagasha, foorarsiga qiimaha saxda ah iyo foorarsiga qaansada weyn.

Marka lagu daro maktabadaha qalabka sare iyo hoose, maktabad kastaa waxay leedahay 50 qalab oo wax lagu qoro.Hordhaca barnaamijka iyo barnaamijka

Hawlaha xulashada.

Shaqada ogaanshaha II/O, waqti ku baar dhibaatooyinka nidaamka iyo qalabka.

Shaqada tirinta shaqada, miisanku wuu kordhiyaa hal mar mar kasta oo barnaamijku socdo

X-dhidibka hore ee xadka shaqada, adoo dejinaya xadka hore ee dhidibka X ee xuduudaha caaryada hoose.

Jiid & dhaqaaji shaqada dib u dhigista

Magdhowga leexintu waxay qabataa habka magdhowga farsamada si loo hagaajiyo xasilloonida alaabta.

Shaqada joogsiga otomaatiga ah ee mashiinka hydraulic, joogsiga tooska ah ee wakhtiga aan shaqayn si loo gaadho saamaynta badbaadinta tamarta.

Shaqada xasuusinta beddelka saliidda Haydarooliga, xasuusin otomaatig ah oo lagu beddelayo saliidda hadhka ka dib 900 saacadood oo socda.

qeexida alaabta

| Mashiinka foorarsiga ee branda CNC | Dhererka miiska (mm) 3100mm | |

| Model WSD10031 | Fogaanta tiirka (mm) 2600mm | |

| Awooda farsamaynta 100T | Heighi miiska 790mm | |

| Nambarada kontolka DELEMLaimore | Moolka dhuunta (mm) 400mm | |

| Nidaamka Servo Fuji | Dhirbaaxada ofram mm 200mm | |

| Servo motor Fuji | Dhererka xiran (mm) | |

| Kooxda cadaadiska cadaadiska Yuken | Xawaaraha ku dhow (mm/sek) 160 | |

| Miisaanka magnetic GIVI | Xawaaraha shaqada (mm/sek) 10 | |

| Giraanta shaabadda Haydarooliga NOK (Japan) | Xawaaraha soo celinta (mm/sek) 130 | |

| Xaddid beddelka OMRON[Japan] | Matoorka ugu weyn (KW) 7.5KW | |

| Xoog (KN) 1000KN | Miisaanka (KG) 8700 | |

| WSD CNC biriiga riix Taxane gaar ahationsCabirka (mm)L*W*H | |||||||||||||

| WSMode | WSD50/12 | WSD63/25 | WSD100/31 | WSD100/40 | WSD160/32 | WSD160/40 | WSD220/32 | WSD220/40 | WSD250/40 | ||||

| Standaro | Daaha Wallndustry | ||||||||||||

| Ku qasbi KN | 500 | 630 | 630 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 | 2200 | 2200 | 2500 | |

| Dhererka foorarsiga mm | 1220 | 2500 | 2500 | 3100 | 4000 | 4000 | 4000 | 3200 | 4000 | 3200 | 4000 | 4000 | |

| Masaafada tiirka mm | 1160 | 2100 | 2100 | 2600 | 3300 | 3300 | 3300 | 2700 | 3300 | 2700 | 3300 | 3300 | |

| Dhererka Norktablemm | 770 | 760 | 760 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 790 | 810 | |

| Faaliga ram mm | 200 | 150 | 200 | 200 | 200 | 200 | 250 | 200 | 200 | 200 | 200 | 250 | |

| Dhererka xiran mm | 410 | 420 | 470 | 470 | 470 | 470 | 520 | 470 | 470 | 470 | 470 | 520 | |

| Dhererka dhuunta mm | 255 | 250 | 250 | 400 | 400 | 500 | 500 | 400 | 400 | 400 | 400 | 400 | |

| Dhererka cunahamm | 540 | 500 | 500 | 550 | 550 | 550 | 575 | 530 | 530 | 530 | 530 | 570 | |

| Xawaaraha rammm/s | u soo dhawaansho | 180 | 130 | 130 | 160 | 160 | 160 | 160 | 130 | 130 | 120 | 120 | 110 |

| shaqaynaysa | 15 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 9 | 9 | 9 | |

| soo noqod | 180 | 110 | 110 | 130 | 130 | 130 | 130 | 100 | 100 | 95 | 95 | 95 | |

| dhidibka strokemm | 500 | 500 | 500 | 500 | 500 | 600 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Bacxgouge posiion irid gode]mm | 900 | 900 | 900 | 900 | 900 | 1000 | 850 | 900 | 900 | 900 | 900 | 900 | |

| Matoorka ugu muhiimsan ee Kw | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 15 | 18.5 | |

| 4000 | 4700 | 5700 | 8700 | 9300 | 9500 | 9500 | 11400 | 13400 | 14100 | 15200 | 20000 | ||

| Dimensionmm | L | 1600 | 2690 | 2690 | 3250 | 4080 | 4200 | 4150 | 3360 | 4080 | 3370 | 4080 | 4250 |

| W | 1580kii | 1370 | 1370 | 1610 | 2600 | 2000 | 1710 | 1810kii | 1810kii | 1850kii | 1850kii | 1850kii | |

| H | 2470 | 2570 | 2570 | 2610 | 1570 | 2720 | 2810 | 2720 | 2720 | 2810 | 2810 | 2910 | |

show faahfaahsan